Introduction

Ajza Sanat Sepahan is a full experienced and well known manufacturer of all types of conveyor systems components and has a close cooperation with many famous and big industries in Iran.

Here for all projects we follow the standard manufacturing process and prepare the necessary documents such as QCTM for all components before fabrication with essential information such as WPS, PQR, ITP, Approved Vendor List, Shop drawings, etc. submitting them to our clients or third party inspectors for review and approval and will follow the inspections according to the approved client Inspection Test Plan.

The planning department prepares a WBS and a timeline and will report to client the progress periodically. Also the quality control department monitors all procedures to ensure about the quality within standard limitations.

The field of our activities:

- Conveyor system

The main component of a conveyor system is pulley or drum which is made here for various applications. The following types are made by us:

- Drive drum / Drive pulley for putting force to the belt and running the conveying system.

- Bend drum / Bend pulley for changing the direction of the belt traveling.

- Take up drum / Take up pulley for providing tension of the belt

- Tail drum / Tail pulley for locating in discharge terminus of the conveyor system.

- Snub drum / Snub pulley for increasing the arc of contact and support the driving force in the conveyor system.

- Special drum / Special pulley for some special applications.

Pulleys are designed and manufactured based on the conveyor capacity , belt trailing , conveyor width according to global standards such as DIN , ISO , JIS , CEMA in our company and all necessary tests including NDT/ DT as well as the material analysis are performed during the production process and valid certificates will be issued for clients.

In some cases the pulleys are covered to improve the grip of drum to belt, reducing risk of slip, causing less belt wearing and make a smoother running.

According to our client requirement and depending on application, we apply different kinds of covering such as PVC, PU, Rubber and Hot vulcanized rubber with various thickness and shapes.

The other components of the conveyor systems which are made by us are following:

- Conveyor structure

- Various types of idlers

- Chutes

- Take up system

- Skirt boards

- Belt cleaners

- Rollicks

- Various types of mechanical devices

- Mechanical equipments by order

- Precise parts and components

- Casting and machine works

- Special structures

- ….

Performance guarantee test and warranty will be provided for all our products in order to make our clients sure about the quality assurance.

Certificates for all jobs will be handed over to client.

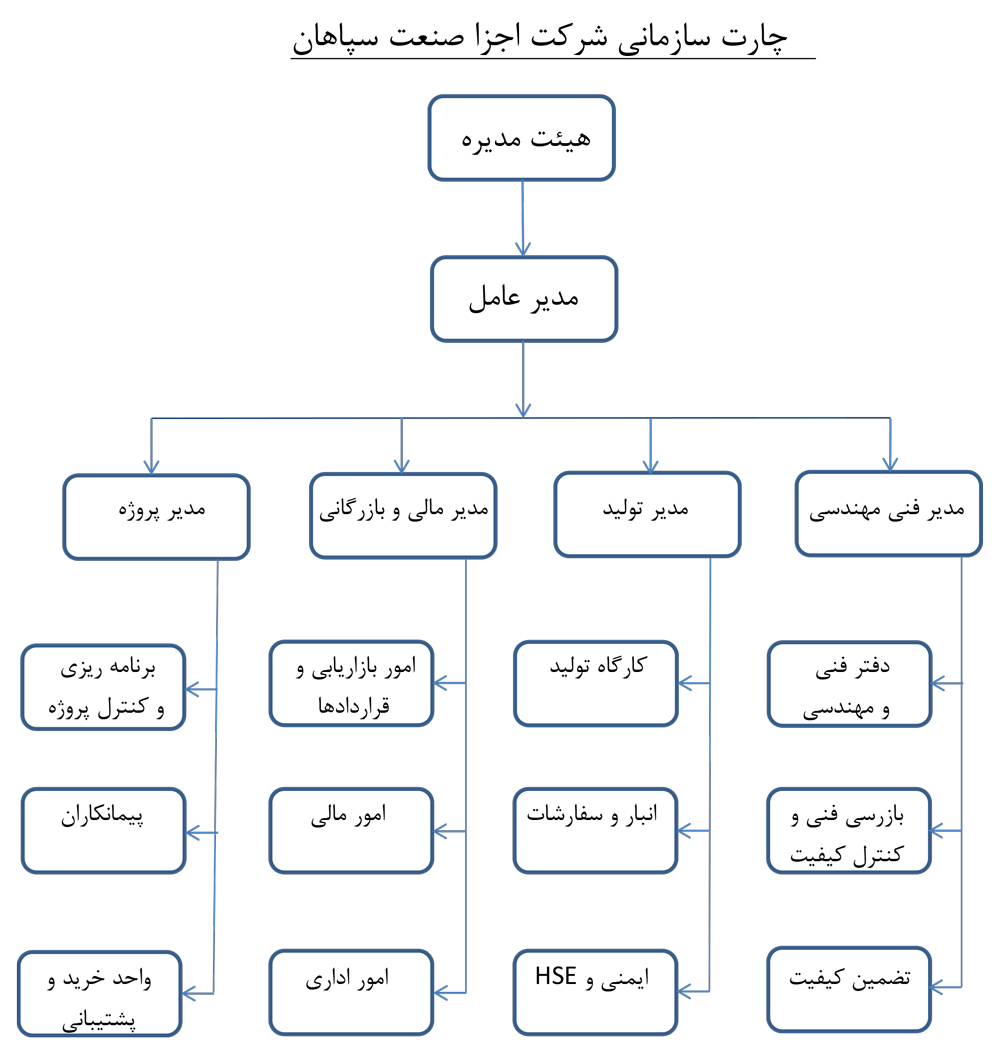

Chart

Vision

The strong quality check division of ours ensures that the best of the products in terms of quality is delivered to our clients. Our crew of experts maintains a strict vigil on the quality of the sourced products for the satisfaction of our clients.

Mission

Our mission is to offer quality products efficient pre-sales and after-sales support. We are spreading our wings to provide latest technology to our clients all over the country. Our commitment for quality is the defining parameters for our progressive growth in this industry.

The strong quality check division of ours ensures that the best of the products in terms of quality is delivered to our clients. Our crew of experts maintains a strict vigil on the quality of the sourced products for the satisfaction of our clients.